What is Cross Docking?

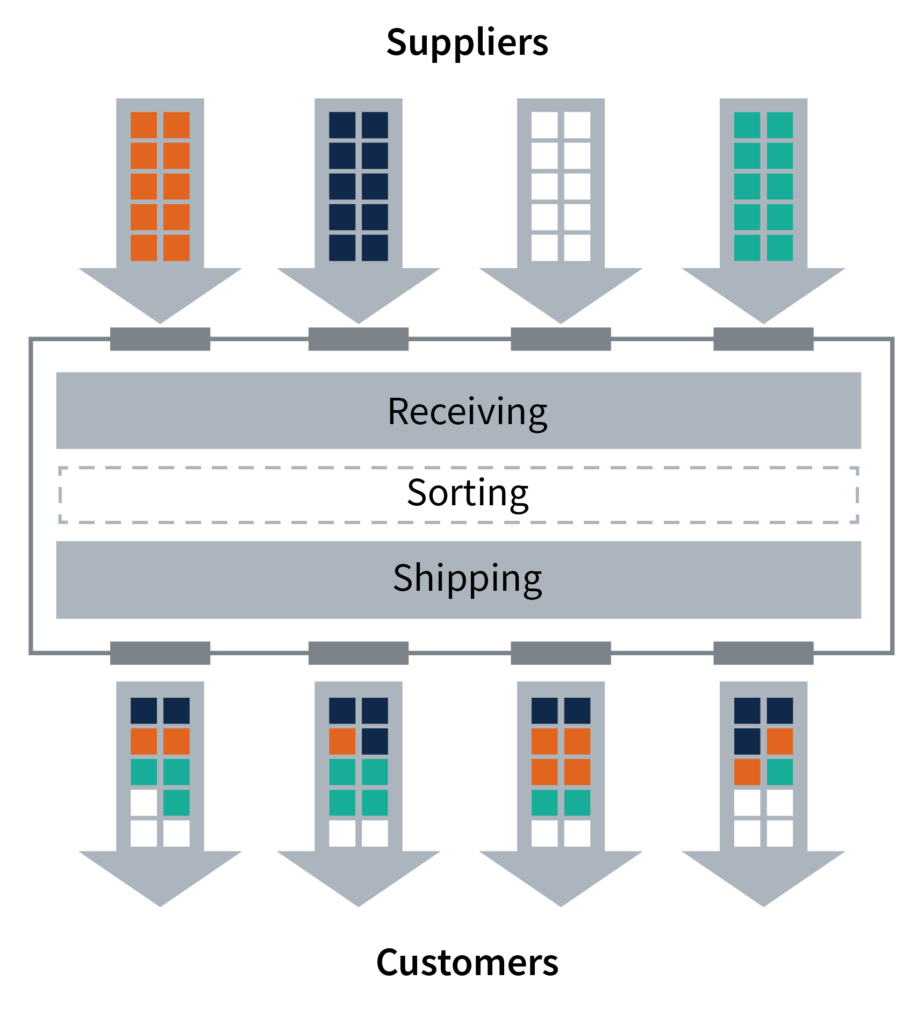

In simplest terms, cross docking is the practice of unloading product from incoming transport and reloading that product for outbound distribution with little-to-no warehousing or storage time between.

This might mean unloading cargo containers that arrive directly to a warehouse by rail line and loading transport trucks for outbound distribution. It could be receiving product in dry-vans and transferring it to flat-deck for job site unloading. Whatever the method of conveyance, cross docking offers the flexibility to design an effective supply chain for any business requirement.

How Can Cross Docking Benefit You?

Cross docking enables shippers, manufacturers and distributors to:

- change the type of conveyance when end-users can’t be reached by a single method

- realize cost savings and economies of scale by shipping high volumes of product at one time

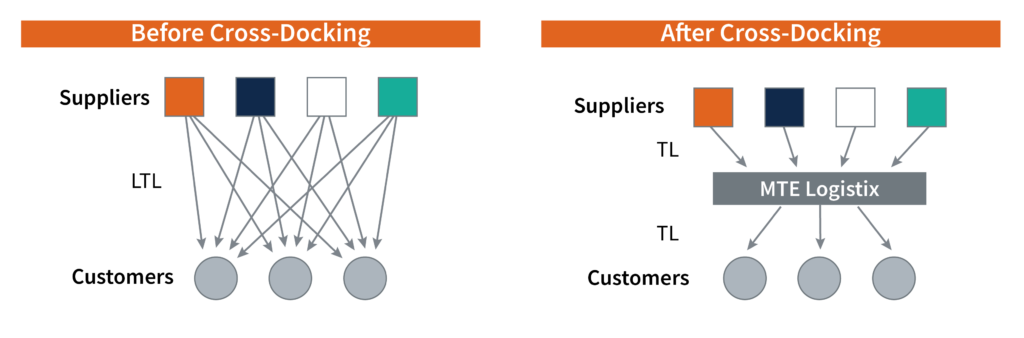

- combine product from different origins in any arrangement or volume

- coordinate distribution to similar destinations or to multiple end-users

Often, cross docking involves breaking bulk pallets for sorting and re-palletizing, before shipping to an end user customer or distribution facility. Product can be reloaded for outbound distribution in the same quantity that it came in at, or in different quantities at different times to different locations.

Cross docking allows you to modify your supply chains to suit your procurement levels, while your 3PL partner sees to the logistic details. Acting as an intermediary, your 3PL takes responsibility for managing the total volume of incoming product, and coordinating the distribution of outgoing product.

Are you looking for a 3PL partner? MTE Logistix has the facilities, equipment, technology and expertise to meet virtually any need.

Give us a call at 780-944-9009 or email info@mtelogistix.com to learn what MTE can do for you!